2024-03-12

2023-12-20

2023-12-20

2023-12-18

2023-11-22

2023-11-06

Address: 3F , Blg 7 West, Sinosteel Building,Maque Industry Village Nanshan,Shenzhen,518057,Guangdong

Phone: +86-755-26971006

Mobile: 13751075276

Email: sales@acroview.com

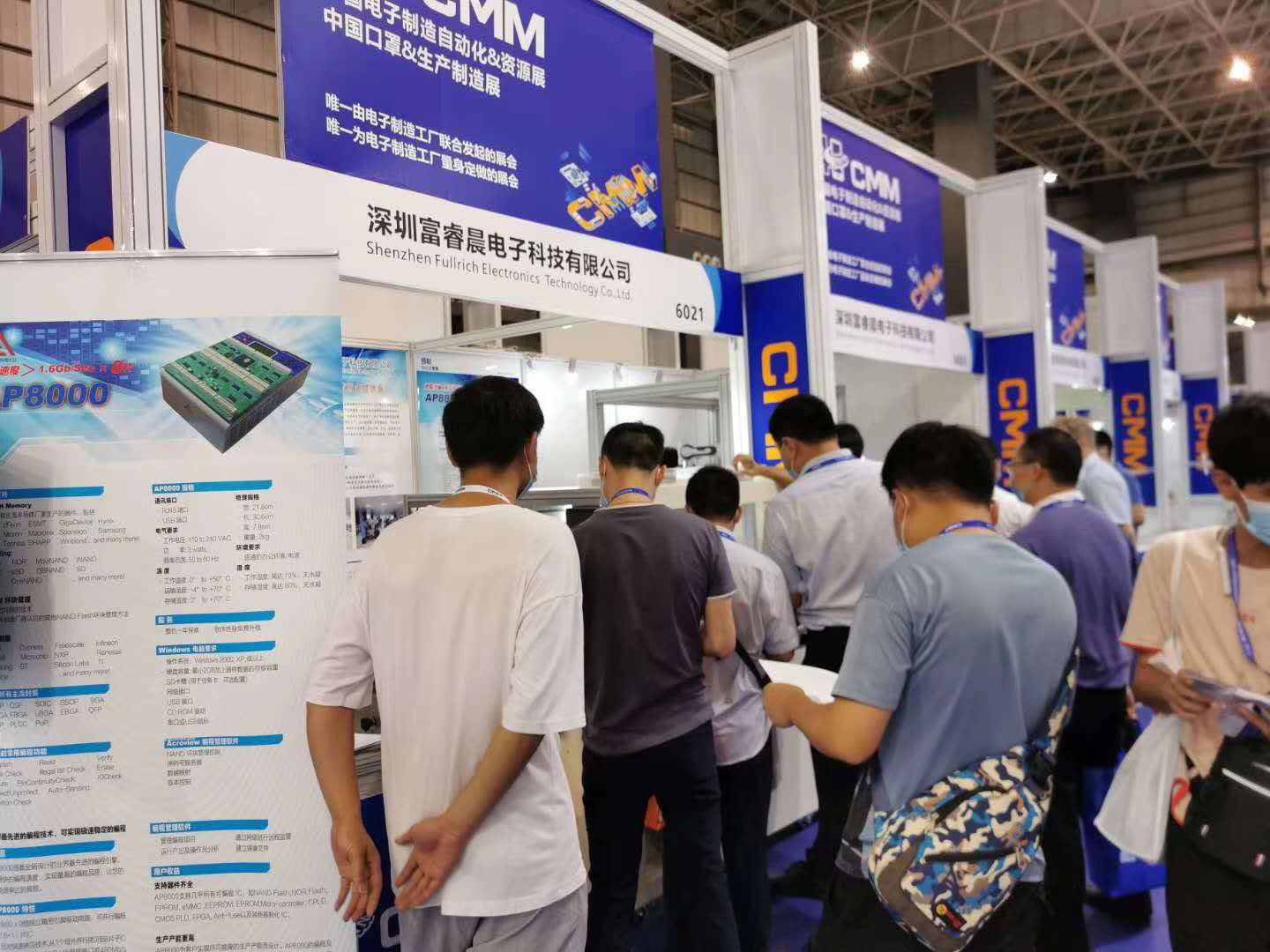

In July, focus on Dongguan. People are watching, live up to expectations!

On July 9, the 4th China Electronics Manufacturing Automation & Resources Exhibition and 2020 CMM China Mask & Manufacturing Exhibition, which has attracted much attention from the electronics manufacturing industry, opened successfully!

Let us take a look at those wonderful moments on the opening day of the exhibition.

Audience Admission

Anti-epidemic and visiting exhibitions did not go wrong, starting the first exhibition after the epidemic in Dongguan.

Exchange Popularity

CMM exhibition is not only a professional platform for exhibiting companies to display products and brands, but also a platform for industry technology, trend, problem exchange and learning.

Exhibitors and exhibits

New product release, new technology display, brand promotion, all-round help exhibitors "Bright Sword" exhibition site.

Acroviewtech joined hands with its agent Shenzhen Fu Ruichen Electronic Technology Co., Ltd. to exhibit the latest automation equipment IPS5000, and received the favor of many old and new friends

IPS5000 automatic burner is the latest product of Onco. It supports CSP and small package programming, such as 1.5x1.0mm size IC, and records and ESD monitoring of various operations during the programming process, making programming more Simple and reliable.

Different types of ICs such as EEPROM, NAND/NOR FLASH, MCU, CPLD, EMMC, UFS... etc. can be automatically burned on the system, whether it is pallet, tape or tube packaging, and the system can be expanded to 64 The burning station, when facing large-capacity ICs, such as UFS/eMMC/Nand Falsh, will not cause the system to be idle and reduce production capacity due to the long burning time.

feature of product

High productivity

Up to 3000 UPH (Unit Per Hour)

Support various feeding and discharging methods

In/out of materials: tube, tape, tray

Widely support various IC types

1. Support IC types: UFS, eMMC, Nor Flash/Nand flash, EEPROM, CPLD, FPGA, Anti-fuse and other customized chips/modules

2. Support IC packaging: SOP, SSOP, TSSOP, PLCC, QFN, BGA, WLCSP... etc.

High expansion

It can be embedded with eight Onco universal burner AP8000, which can be expanded to 64 burner sockets

Innovative CAP cover design

Automatic burning system, each burning seat is equipped with a CAP cover, which improves the uniformity of the burning seat force and prolongs the service life of each burning seat.

Quick commissioning and line change

It is convenient to change the debugging coordinates of the programming line, and each coordinate parameter can be copied in a unit, quickly mapped, and CCD auxiliary line change;

Stacking inspection

Support software stacking detection and hardware stacking detection, full protection, adapt to all kinds of chip applications in all scenarios;

ESD monitoring

3 sets of double-head ion fans can be built in, ESD monitoring throughout the entire process to ensure that they are not affected by static electricity during the entire programming process;

MES Manufacturing Execution System

In order to support various MES docking and simplify the docking process, ACROVIEW provides a set of standard solutions; customers can also develop their own interfaces according to the programming secondary development interface provided by the system. If there is no complete MES system, production task management can also be carried out through the simplified EXCEL method;

Various optional functions

Laser printing, labeling, inkjet printing, 2D inspection, 3D inspection

设备能力 | 芯片搬送速度 | 64个芯片取放搬送,最慢247秒 ※包括芯片取放前的定位 | ||

单位小时生产的数量(UPH) | 理论计算方式 (64个烧录座同时烧录) | |||

托盘装载 | 装载形式 | 叠加、抽屉式和半飞达式 | ||

対象托盘 | JEDEC | |||

収納数 | 烧录前 | 20盘 | ||

烧录良品 | 20盘 | |||

不良収納 | 1盘 | |||

空托盘缓冲 | 3盘 | |||

飞达供给 | 2卷 | |||

托盘搬送 | 脉冲马达 + 皮带驱动 | |||

芯片搬送 | X、Y、Z1-4、θ 7轴 螺杆+步进电机驱动 | |||

分解能 | X搬送最小分解能 1um/脉冲 | |||

Y搬送最小分解能 1um/脉冲 | ||||

Z1-Z4搬送最小分解能 1um/脉冲 | ||||

θ轴回転角度 0.036°/脉冲 | ||||

IC搬送 | 搬送JAM率 | 1/1000以下 | 托盘变形、芯片不良等原因除外 | |

接触不良对策 | 错误重试机制 | 摆放不良时可于机台重试 | ||

芯片吸附错误対策 | 吸着错误发生时、可进行重试动作。多次重试不良时报警。 | |||

坐标登录方法 |

Last article:The second day of CMM exhibition | Acroviewtech's UFS burner booth was full of rewards, and it Next article:Acroview Technology meets you at CMM Exhibition 2020 Dear, scan to add WeChat as a friend Online Service Phone Wechat Top | |||