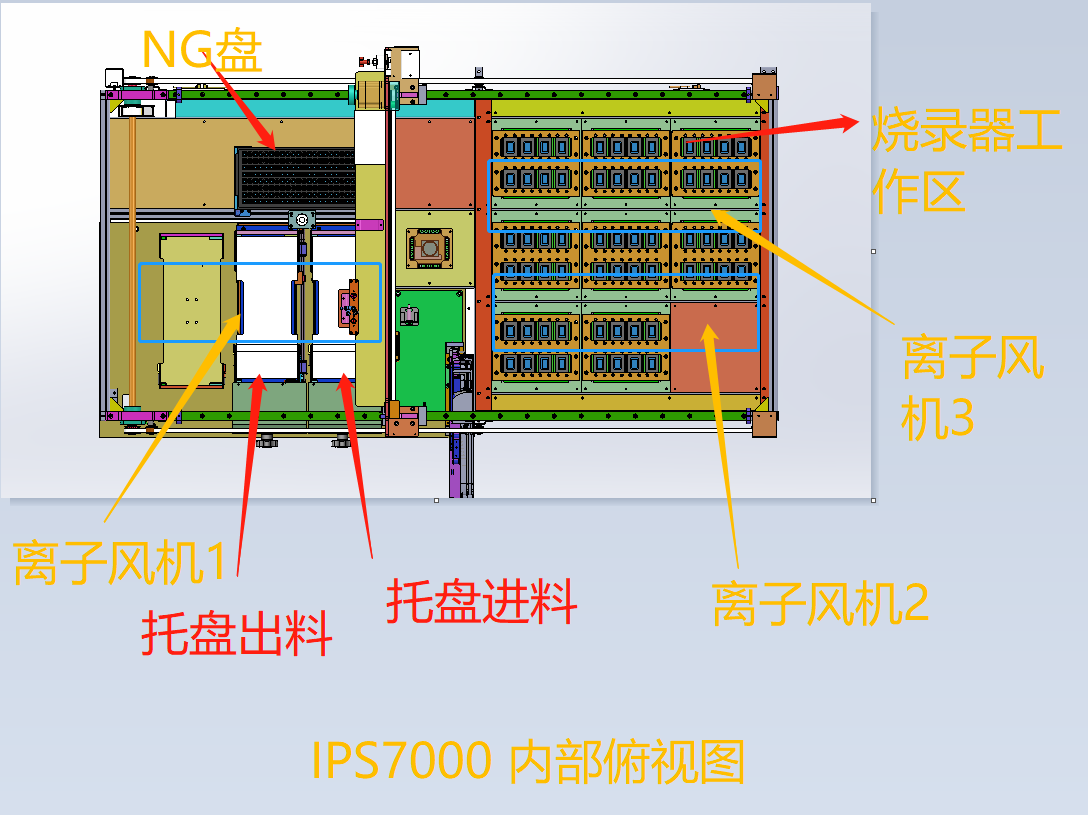

■Equipped with 8 newly developed universal programmer, the speed is 40% faster than the original equipment.

■ The writer can be directly connected via LAN for easy wiring. The original program can be downloaded at high speed through the network port.

■ Equipped with 8 universal with 8 universal sockets, reasonable interactive operation among each other realizes the high-speed production efficiency.

■ The standard camera is equipped to realize the image correction in the automatic production process, and can be flexibly used for the registration of various data center coordinates. Through this function, the cumbersome slot coordinate positioning can not only be completed with one key, but the chip misalignment caused by the tray reset can also be automatically corrected during operation.

■ The standard down-illuminated camera can realize the automatic compensation of socket coordinates, automatic registration of Tray disk coordinates, and IC/module QR code reading and other advanced functions more conveniently.

■ Model conversion can be easily completed without any special tools.

■ Equipped with a large-size LCD touch screen, large-capacity AutoTray, MES correspondence, superior production log management and other unique functions of the PH series.

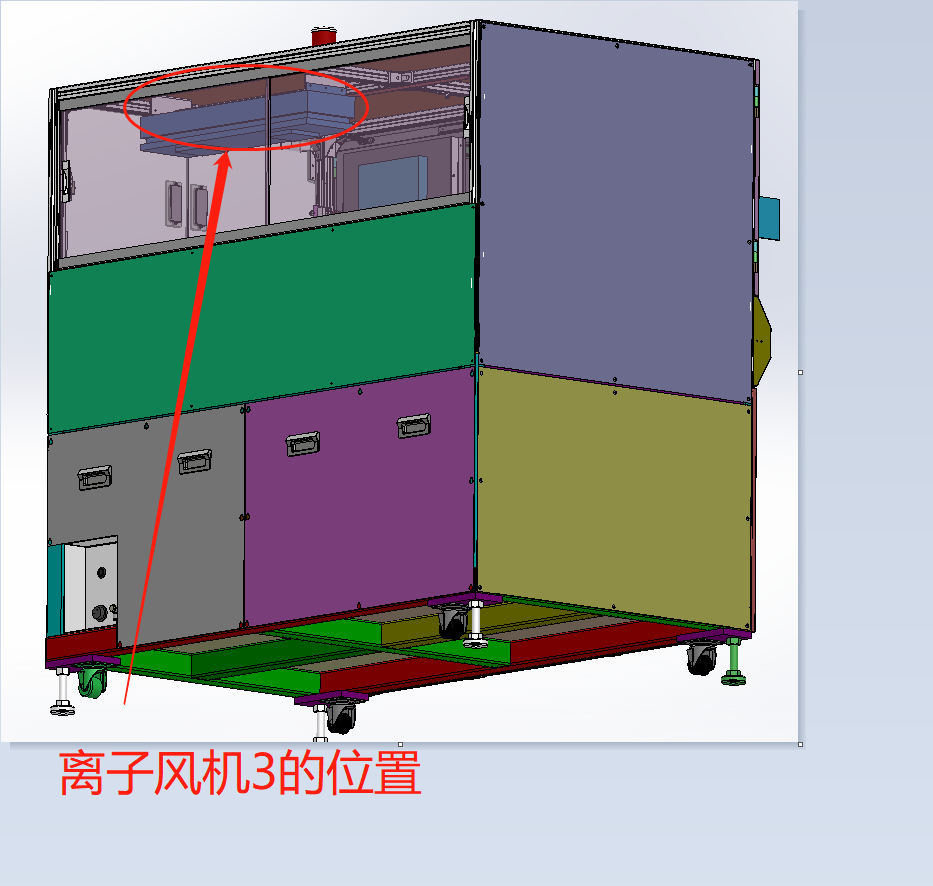

■ The compact and reasonable design makes the device with the ability to burn 64 chips at a time also appear compact in structure and reasonable in layout.

■ Flexible corresponding to various flat chips (TSOP, CSP, QFP, TQFP, μBGA, etc.).

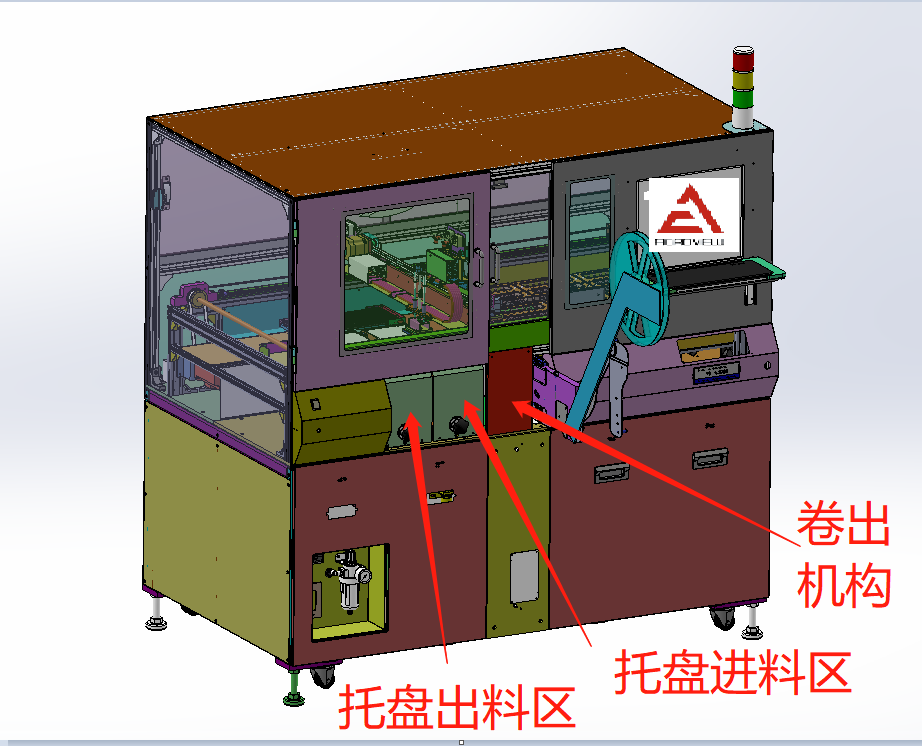

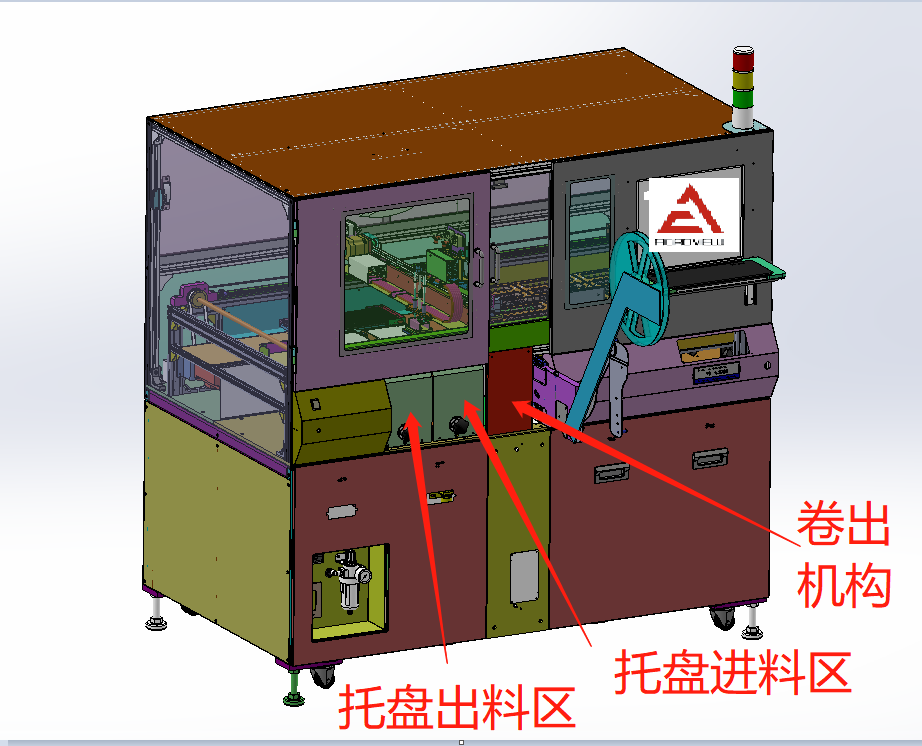

■ The pallet carrier can load up to 20 JEDEC pallets.

■ Optional Tape In/Tape Out, TubeIn/Tube Out, can flexibly realize the flexible transfer packaging correspondence between Tray/Tape/Tube.

■ XYZ1Z2Z3Z4θ5-axis high-precision servo stepping hybrid control realizes high-speed, high-precision and stable product handling.

■ PPZ adopts double-head design, which makes the conveying efficiency higher and faster.

■ PPZ four-axis can realize the same fetching and placing in the socket through the positioning of the fixture, further improving the conveying efficiency.

■ Optional Stamp mechanism can meet the needs of Tray/Tape/Tube stamping.

Program Universal

Universal: A8000 (Acroview) 8

Corresponding chip: Flash memory chip, monolithic internal memory memory

Programming sequence: data erasure (Erase), blank check (Blank), program writing (Program),

Verity can be reprogrammed according to different requirements

External interface: LAN

processor

Corresponding types: TSOP, BGA, QFP, TQFP, SOP and other chip packages

Corresponding slot: dedicated for open top slot

Processing capacity: MAX 1300

(When 8 sets*8 ports, the IC does not affect UPH within 170S of programming time)

Chip transportation: 7-axis 4-head high-speed P&P servo stepping motor hybrid drive

X-Y minimum resolution: 0.004 mm

Reset accuracy: ±0.02 mm

Minimum resolution of θ axis: 0.18°

Fully automatic coordinate login: optional

Pallet loader: corresponding to pallet JEDEC, EIAJ

Before programming, load 20

Program burning good product loading disk number 20 disks

Number of defective products: 1 tray

Mark printing: Standard installation: Printers for pigment inks sold on the market

Optional equipment: semiconductor-specific ink printer that is not easy to fade

Dot mark, text mark possible

Operating system: FA PC OS: Windows 10

Input device: LCD touch screen, keyboard, code reader (optional)

Support network: Ethernet

Model conversion time: 10 minutes or less (but not including ROM data transfer time)

Use air: 0.4Mpa-0.5Mpa 50 l/min

Power supply: 100-220V AC 50/60Hz 15A about 1300VA

Device size and weight: (D) 1140, (W)1300, (H)1500 (mm) about 700Kg